What you should know about the composite fence

Fencing isn’t just about marking boundaries—it’s about enhancing curb appeal, boosting property value, and enjoying years of worry‑free privacy. In a world flooded with wood, vinyl, and metal options, composite fencing has emerged as the clear winner for homeowners, contractors, and distributors alike. But what exactly is composite fence, and why should you make it your go‑to choice today? In this in‑depth guide, we’ll uncover the magic behind wood‑plastic composite panels, tackle your burning FAQs, spotlight industry leaders like Trex® and MecoFence®, and arm you with actionable strategies to get the most from your next fencing project.

What Is Composite Fencing?

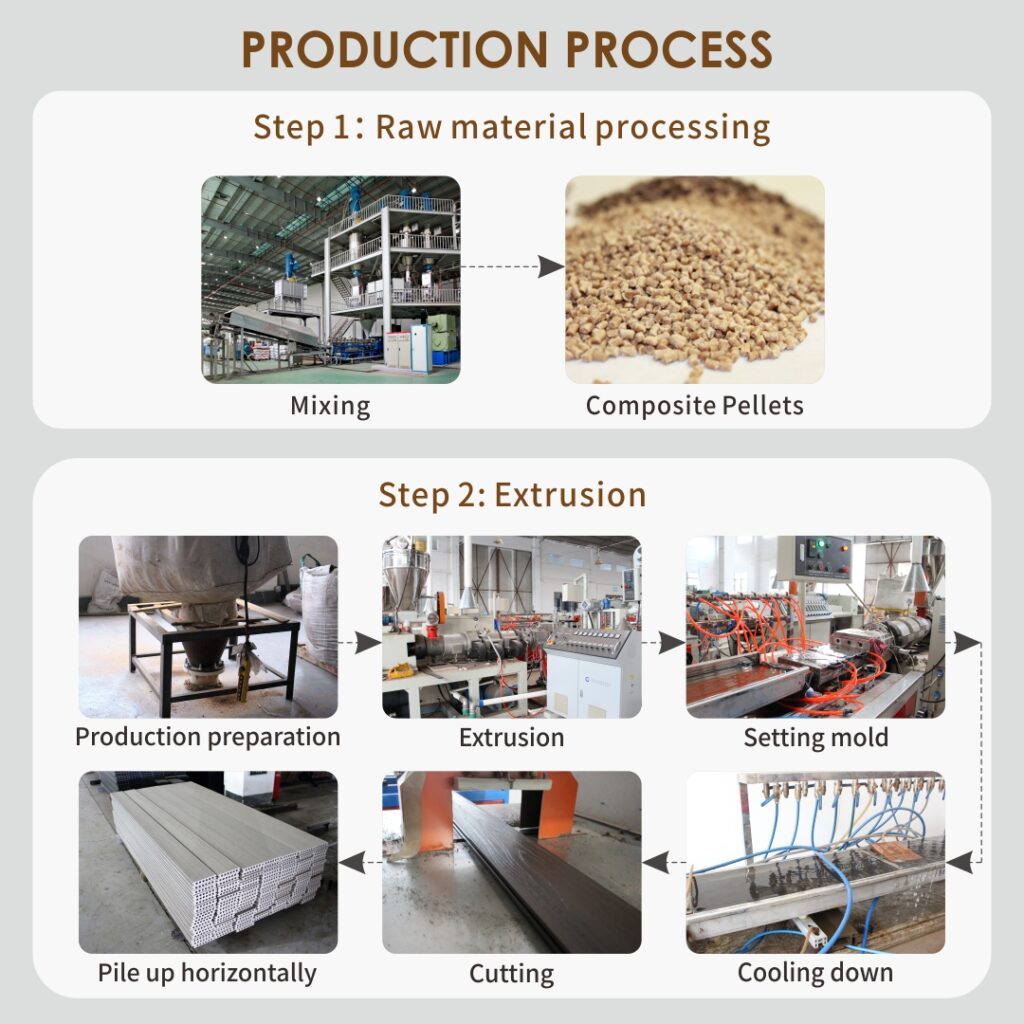

Composite fencing combines recycled wood fibers and high‑density polyethylene (HDPE) to create panels that look and feel like real wood—but without the headaches.(Please refer to the following figure for the production process)

Composite Fence Materials: Key Components and Their Benefits

1. Wood Fiber (Approximately 65%)

Wood fiber is the main ingredient in composite fencing. It gives the fence a natural wood-like look and feel, contributing to its aesthetic appeal. The finely processed wood fibers also provide strength and rigidity to the material, ensuring that the fence retains the desirable qualities of traditional wood while benefiting from increased durability.

2. HDPE (High-Density Polyethylene) (More than 30%)

HDPE is a durable plastic material that resists moisture, rot, and insect damage, making it ideal for outdoor use. According to MecoFence Manufacturer, more than 30% HDPE is used in their composite formulation, ensuring that it completely encapsulates the wood fiber. This encapsulation helps protect the wood fiber from the elements while adding strength and resilience to the entire fence structure. By using a higher percentage of HDPE, the fence maintains its integrity, ensuring that it performs well under harsh weather conditions without degrading over time.

3. Additives (Approximately 5%)

- Stone Powder: This additive improves the material’s overall strength and durability, helping to prevent cracking and splintering over time.

- Coupling Agent: A bonding agent that ensures the wood fiber and HDPE blend well together, strengthening the composite material.

Compound Lubricant: Used during manufacturing, this additive reduces friction, making it easier to mold and shape the material while also maintaining its flexibility.

Antioxidants: These prevent the HDPE from oxidizing, which can cause discoloration and weaken the material.

Anti-UV Agents: These agents protect the composite from harmful UV rays, helping to prevent fading and degradation from sun exposure.

Anti-Mildew Agents: These additives prevent the growth of mold and mildew, which is especially important in humid climates, ensuring that the fence remains clean and resistant to organic growth.

5. Co-Extrusion Layer

The Generation 2 composite fences include a co-extrusion layer made from Surlyn resin, a material often used in golf ball coverings due to its durability. This layer enhances the fence’s resistance to scratches, UV damage, and stains, providing a smooth and protective surface. Surlyn resin is known for its toughness, which helps preserve the fence’s appearance and structural integrity, even in harsh environmental conditions. Additionally, this layer makes the fence easier to clean and more resistant to wear and tear over time.

Key Features of Composite Fence

Unlike pure wood that rots, vinyl that fades, or metal that dents, composite panels deliver:

Durability: Lasts 20–30 years with minimal signs of wear.

Low Maintenance: No sanding, staining, or painting—just an annual rinse.

Aesthetic Versatility: Rich wood‑grain textures in colors like Cedar, Slate Gray, and Weathered Teak.

Eco‑Friendly Credentials: Diverts over 95% of plastic waste from landfills and uses up to 60% recycled wood content.

1. Durability & Longevity

- 20–30 Year Lifespan: Industry data shows composite fencing outperforms wood by 2–3x in service life, resisting rot, warp, and insect damage.

- UV & Weather Resistance: Advanced color‑locking technology prevents fading and chalking, even under intense sun exposure.

- Warranty Peace‑of‑Mind: Leading brands like Trex® offer 25‑year limited warranties against structural failure.

2. Low Maintenance Means More Free Time

- No Painting or Staining: Factory‑applied color finish won’t peel or blister.

- Quick Clean‑Up: Annual soap‑and‑water wash takes just 5 minutes per panel—no special cleaners required.

- Cost Savings: Skip the $300–$500 per coat painting every 2–3 years—you’ll save thousands over a fence’s lifetime.

3. Aesthetic Versatility to Match Any Vision

- Endless Textures & Hues: Choose from wood‑grain panels like Trex Enhance™ or deep‑grain matte finishes from MecoFence®.

- Customizable Styles: Privacy, picket, slat, and lattice‑top designs allow for tailored curb appeal.

- Accessories & Accents: Matching gates, post caps, and integrated LED lighting make your fence a showpiece.

4. Eco‑Friendly & Sustainable

- Recycled Content: Up to 60% reclaimed wood fibers and 40% recycled plastic reduce reliance on virgin materials.

- Landfill Diversion: Over 95% of manufacturing scrap is repurposed, supporting circular‑economy goals.

- LEED Points: Installers can earn credits toward green building certifications when using composite fencing.

5. Head‑to‑Head Comparison

| Feature | Composite Wood | Wood | Vinyl | Metal |

| Lifespan | 20–30 years | 5–10 years | 20–25 years | 30+ years |

| Maintenance | Annual rinse | Painting/staining every 2 yrs | Occasional rinse, no paint | Rust prevention in steel |

| Aesthetics | Deep-grain wood textures | Natural warmth, but ages | Limited color depth | Modern, but “cold” finish |

| Eco‑Credentials | 60% recycled wood & plastic | Harvested timber | 100% virgin PVC | High embodied energy |

Composite fencing has revolutionized boundary solutions by combining the best of wood’s natural beauty with plastic’s unmatched durability. Brands like Trex®, Fiberon®, and MecoFence® are raising the bar with rich textures, sustainable manufacturing, and warranties that guarantee peace of mind. Whether you’re a homeowner seeking a low‑hassle upgrade or a contractor pursuing the latest high‑margin product, composite fence delivers on every front: longevity, style, eco‑credentials, and maintenance simplicity. Don’t settle for temporary fixes—invest in a composite barrier that stands strong and looks stunning for decades.