Introduction: The “Paper Tiger” of the Fencing Industry

In our 15+ years of manufacturing and supplying global fencing solutions—shipping over 2,100 containers annually to every continent—we have seen thousands of project specifications cross our desks. From luxury coastal resorts in the Caribbean to sprawling suburban developments in Australia, one requirement stands out above all others: reliable high wind fencing.

It makes perfect sense. A fence is more than just a boundary line; it is an investment in security, privacy, and peace of mind. No one wants to wake up after a storm to find their investment lying flat on the ground.

However, there is a disturbing trend we continue to witness in the fencing industry. We call it the “Brochure vs. Reality” gap.

You’ve likely seen the glossy marketing materials for standard Vinyl (PVC) fencing. They boldly claim “Miami-Dade Wind Load Ratings.” They promise survival in 100+ mph winds. On paper, they look invincible. But as a manufacturer deeply embedded in the engineering of outdoor materials, we know that paper ratings often rely on “perfect world” scenarios—scenarios that rarely exist on a real, muddy construction site.

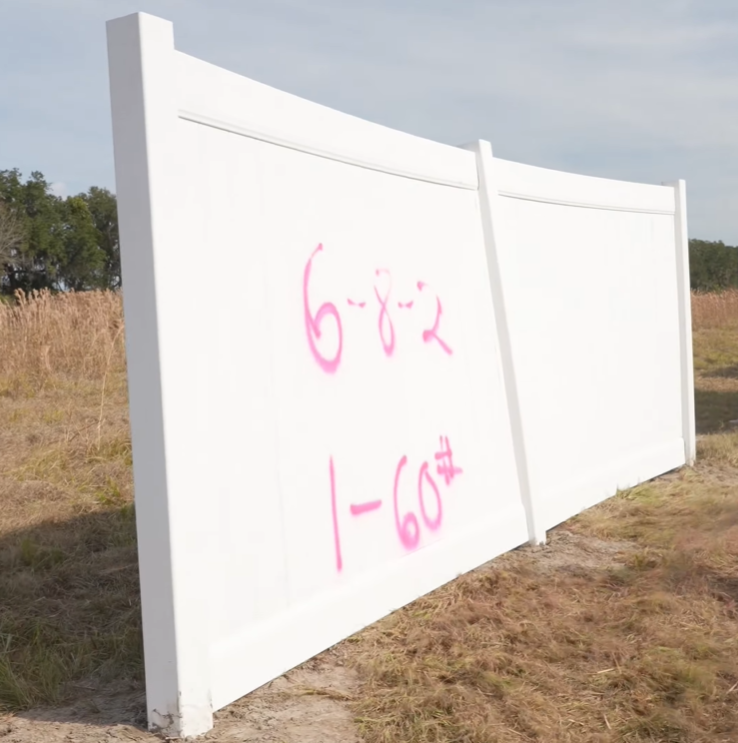

Recent independent field tests—recreating hurricane-force winds with industrial airboats—have visually confirmed what material scientists and honest engineers have known for a long time: Standard hollow vinyl fencing suffers from a specific structural failure mode known as “kinking.”

At MecoFence, we believe in engineering based on physics, not just marketing hype. In this article, we are going to strip away the jargon, dissect the mechanics of fence failure in plain English, and explain why the MecoFence Modular Composite System (WPC + Aluminum) offers a superior safety factor for your projects.

The Physics of Vinyl Fence Failure in High Wind Fencing: Understanding “Kinking”

To understand why MecoFence is the solution, we must first honestly diagnose the problem with the current industry standard. Why does vinyl fail?

It’s not because the wind is too strong. It’s because the material behaves in a way that is unforgiving.

The “Drinking Straw” Effect: How Hollow Posts Collapse

Imagine you are holding a plastic drinking straw. If you push on the ends or bend it slightly, it bounces back. But if you bend it past a certain point, what happens? It develops a sharp crease. It folds. We call this a “Kink.”

Once that straw has a kink in it, it loses all its strength. You can never straighten it out again. It is structurally dead.

This is exactly what happens to a hollow vinyl fence post in a storm. In wind simulation tests, standard 6-foot vinyl posts set in concrete(2-3 feet deep) began to fail at wind speeds as low as 60-75 mph (Tropical Storm force). They didn’t snap in half like a dry twig. Instead, the hollow PVC post buckled and kinked right above the concrete footing. The force of the wind pushing against the privacy panels acted like a giant sail. This “sail effect” transferred massive torque (twisting force) to the base of the post. Because rigid PVC is, by nature, a material that cannot stretch much before breaking, it simply folded.

|  |

The Scary Part: Once a post kinks, your fence is done. It cannot be repaired. The entire system—posts, concrete, and panels—must be dug out of the ground and replaced. For a commercial project, this is a financial nightmare.

The Hidden Truth About Miami-Dade Wind Ratings

You might be asking, “But wait, I saw a vinyl fence rated for 120 mph. How is that possible?”

Here is the industry secret that brochures often hide in the fine print: To achieve those high wind ratings, vinyl manufacturers usually require you to insert heavy-duty aluminum I-beams inside every single post. Effectively, the vinyl becomes just a pretty sleeve, and the metal does all the work.

The Reality: When contractors bid on jobs, especially large commercial ones, they often “Value Engineer” (cut costs) by skipping these expensive metal inserts. The result? The client thinks they bought a hurricane-proof fence, but they actually installed a hollow plastic tube system that will fold like a straw in a Category 1 storm.

The Hybrid Solution: Why Aluminum Post Composite Fencing Outperforms Vinyl

At MecoFence, we looked at this problem and asked a simple question: Why ask plastic to do a job meant for metal?

We realized the only way to build a truly reliable fence was to use a Hybrid Engineering Approach. We use the right material for the right job: Aluminum for the skeleton (bones), and Co-extrusion WPC for the body (muscle).

6063-T5 Marine-Grade Aluminum Posts: Engineered for Yield Strength

The core differentiator of the MecoFence system is the post. We don’t use vinyl. We use 6063-T5 Aluminum Alloy, heat-treated for optimal strength.

Let’s look at why this matters in simple terms:

Elasticity (The “Bounce Back” Factor): Think of an airplane wing. When it hits turbulence, it bends, but it doesn’t break. It flexes and then returns to its original shape. This is called Elasticity. Aluminum has high elasticity. When a 90-mph wind gust hits a MecoFence post, the aluminum will flex slightly to absorb the energy, and then spring back to true. It doesn’t kink. It fights back.

Safety in Failure: No material is indestructible. If a Category 5 hurricane hits, anything can fail. But how it fails matters. Vinyl shatters or kinks suddenly, creating sharp, flying debris. Aluminum is a ductile metal. If it is pushed beyond its absolute limit, it will bend slowly. It won’t snap off and fly through a window. This predictable behavior is a huge safety factor for architects and insurance companies.

Torque Resistance: Our heavy-duty posts aren’t just empty tubes. If you look at the cross-section (the cut end) of a MecoFence post, you will see internal ribs. These are like the beams in a skyscraper, designed specifically to stop the post from twisting or crushing under wind pressure.

High-Density WPC Fence Boards: Dampening Vibration & Flutter

Wind load isn’t just about static pressure (like leaning against a wall); it’s about vibration.

The “Flutter” Problem: Have you ever seen a vinyl fence in a storm? It vibrates violently. It shakes and rattles. This high-frequency shaking acts like a jackhammer on the concrete footing below. Over time, this “flutter” liquefies the soil around the concrete, causing the post to lean, even if the post itself doesn’t break.

The Mass Damping Solution: MecoFence WPC (Wood Plastic Composite) panels are high-density. They are heavy and solid. Just as a heavy stone wall doesn’t vibrate in the wind, the sheer mass of our composite boards acts as a dampener. They sit heavy. They don’t rattle. This stability protects the integrity of your concrete footing, keeping the fence standing straight year after year.

No “Blow-Outs”: A common failure in vinyl fences is panel “blow-out.” The horizontal rails are soft plastic. Under wind pressure, they bow outward, and the vertical boards pop out, turning into projectiles. MecoFence uses a deep-channel aluminum rail system. The rigidity of the aluminum rail holds the panels in a vice-like grip. They cannot bow. They cannot pop out.

System Integrity: How Our Modular Interlocking Design Prevents Blow-Outs

The field tests we analyzed highlighted that “tight connections” are critical for survival. If a fence is loose and sloppy, it falls apart. MecoFence takes this concept to the next level with precision engineering.

Creating a Monolithic Wall Against Wind Pressure

In a standard fence, you often have separate pieces rattling around. MecoFence boards feature a Tongue-and-Groove design. This means the top of one board locks into the bottom of the next board. When you stack them up, they don’t act like 10 separate boards; they act like one solid wall. Mechanically, this distributes the wind pressure evenly across the entire surface and transfers it efficiently to the strong aluminum posts.

(Pro Tip for Coastal Zones: If you are building in an area with extreme hurricane requirements, we always recommend our “Semi-Privacy” or “Slatted” designs. Physics dictates that the best way to handle wind is to let it pass through. Our modular system allows you to create gaps for airflow without sacrificing style.)

Chemical Resilience: Defending Against Salt Spray & UV Degradation

Physics isn’t just about force; it’s about time and chemistry. Even the strongest vinyl fence has an enemy: The Sun (UV Rays).

The “Old Tupperware” Effect: Think of an old plastic container left in the sun. It turns yellow and becomes brittle. If you drop it, it cracks. Standard PVC fencing behaves similarly. After 5 years of intense UV exposure, its impact resistance drops significantly. A fence that could withstand a storm when it was new might shatter like glass when it is old.

The MecoFence Shield: Our WPC panels are manufactured using Co-extrusion Technology. This means the core is wrapped in a 360-degree high-polymer shield. This shield is chemically engineered to block UV radiation. It doesn’t chalk. It doesn’t get brittle. Furthermore, our Aluminum posts are Powder Coated to meet AAMA 2604/2605 standards. This is the same coating used on skyscrapers. It is impervious to salt spray and sun. The result? The structural strength you install today is the same strength you will have in 10 years.

Installation Reality: Why Contractors Prefer Rigid Aluminum Systems

We know that engineering is useless if the installation is a nightmare. One of the biggest complaints from installers about vinyl is how “finicky” it is.

The “Wobbly Post” Issue: Because a vinyl post is flexible, it is very hard to set perfectly plumb (straight). If the concrete isn’t mixed exactly right, or if the soil shifts slightly, the post leans.

The MecoFence Advantage: Our Aluminum posts are rigid. While you still need to dig a proper footing (we always follow ASTM standards), the inherent stiffness of the aluminum makes it much easier to set straight. It holds its line. It doesn’t warp in the hot sun while the concrete is drying.

Efficiency in Design: Because our system is Modular, it is a dream for installers dealing with slopes. Vinyl panels often come pre-fabricated in square shapes. If you have a sloped yard, you have to “stair-step” them, which leaves gaps at the bottom. With MecoFence, you can “rack” the fence (follow the slope) or cut the boards on-site to fit any terrain perfectly. No custom ordering required.

Why Trust MecoFence?

You might be thinking, “This sounds great, but why should I trust MecoFence over the dozens of other suppliers?”

We Are The Manufacturer (60+ Extrusion Lines): We are not a trading company. We don’t just buy and resell. We own the factory. We mix the formula. We control the quality of the aluminum alloy and the density of the WPC. We have the capacity to produce consistent quality for massive orders.

Global Track Record (2,100+ Containers/Year): Our fences are currently standing in the typhoons of Southeast Asia, the freezing blizzards of Canada, and the scorching 50°C heat of the Middle East. We have real-world data from every extreme climate on Earth. We know what works because we have seen it work.

Honesty and Transparency: We don’t hide behind vague “Wind Ratings.” We provide detailed installation guides and technical data sheets (TDS). More importantly, we will tell you no. If you ask us to install a solid privacy fence on a beachfront with Category 5 winds, we will advise you against it. We will recommend a slatted design or a reinforced installation method. We prioritize your long-term safety over a quick sale.

Don’t Build for the Best Day. Build for the Worst.

The video evidence from the field is clear. The industry reports are clear. When the wind howls and the pressure builds, plastic kinks.

For a residential homeowner, a blown-down fence is a nuisance and an unexpected $5,000 repair bill. For a commercial developer, a wholesaler, or a contractor, a failed fence is a liability, a reputation killer, and a lawsuit waiting to happen.

The MecoFence Modular Composite System represents the evolution of fencing. We didn’t invent the fence; we just stopped compromising on the materials. By combining the aesthetic warmth of wood-composite with the industrial backbone of aluminum, we offer a perimeter solution that is engineered to stand when others fold.

Don’t rely on luck. Rely on Yield Strength.

Partner with MecoFence. Let’s build boundaries that last.

02/10/2026

Standard hollow vinyl posts typically “kink” (fold) rather than snap. This plastic deformation happens at wind speeds as low as 60-75 mph and renders the post unrepairable.

Yes, but it significantly increases the cost. Many “wind-rated” vinyl fences require these inserts to meet their specs, but contractors often skip them to save money, leaving you with a weak fence.

Yes. MecoFence uses 6063-T5 Marine-Grade Aluminum posts which have a much higher yield strength than PVC. They are designed to flex and recover in high winds, avoiding the catastrophic “kinking” failure of vinyl.