Something you should know before purchasing the WPC Fence

To find the best WPC fence for your needs, it’s essential to understand some tests that guarantee its durability and performance. WPC fences are an excellent choice for durability and low maintenance, but not all are created equal. The right testing can make all the difference in ensuring your composite fence material stands up to the elements. Read on to discover why knowing these key tests is essential before investing in a modern composite fence.

The Importance of WPC Fence Tests

WPC fences, made from a mix of wood fibers and recycled plastic, are designed to offer the aesthetic benefits of wood with the durability of plastic. To confirm their superior performance, rigorous testing is essential. Testing helps ensure that composite fence material can withstand exposure to UV rays, extreme temperatures, and physical stress without compromising its strength or appearance.

Leading composite fence manufacturers like MecoFence understand the importance of these WPC Fence tests. With years of experience in the industry, MecoFence has built a reputation for producing high-quality WPC fences that undergo comprehensive testing at every stage of production. Their commitment to excellence ensures that the composite fence boards they offer are not only visually appealing but also built to last, standing up to the toughest weather conditions.

For anyone considering modern composite fences, understanding these tests—and choosing a reputable manufacturer like MecoFence —is crucial for making an informed decision. When you purchase a fence that’s undergone extensive testing, you can trust that it will stand the test of time.

Key Tests for WPC Fence Board

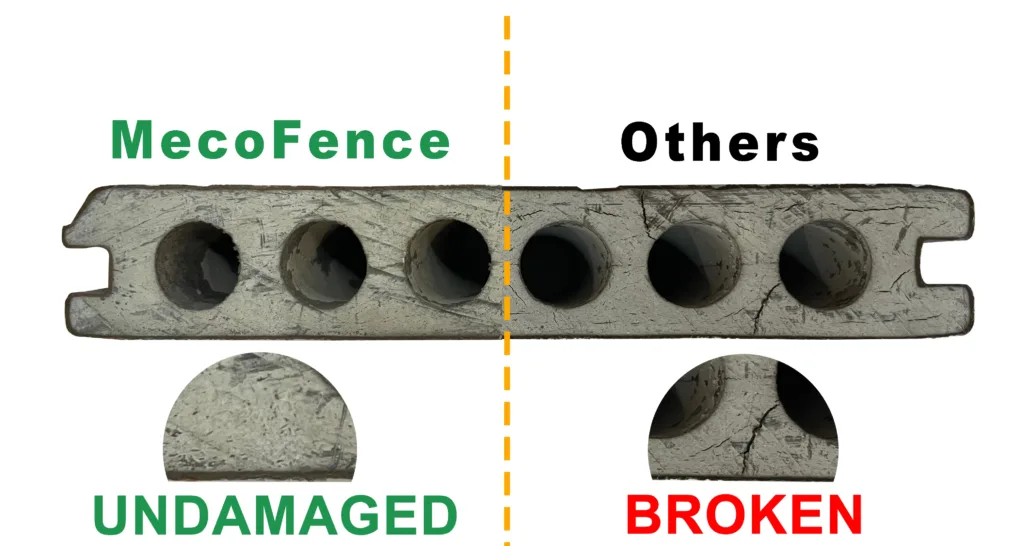

1. Bending Strength Test: Ensuring Structural Integrity

The bending strength test is a key factor when evaluating the performance of WPC fences. This test determines the maximum amount of pressure a composite fence board can endure before it starts to bend or break. A 50 cm long fence board sample is placed on two support poles, 40 cm apart, and pressure is applied until the fence material breaks(Suitable over 2500N). This method simulates external pressures such as wind or accidental impacts.

Why it matters: If your WPC fence can endure bending pressure, it means your fence will perform well in areas prone to high winds or heavy rain, ensuring that your composite fence material remains structurally sound and visually appealing.

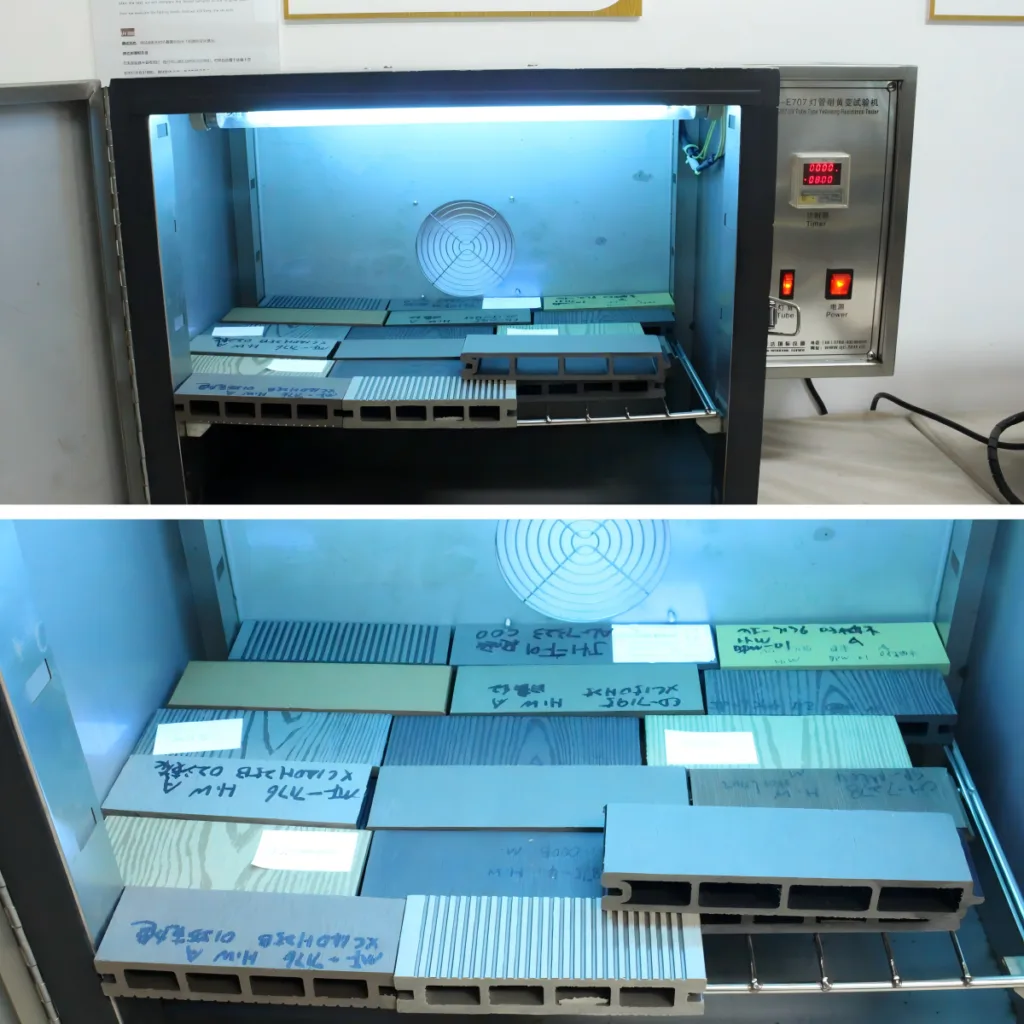

2. UV Test: Protecting Color and Integrity

The UV test is vital for assessing the longevity of a modern composite fence in direct sunlight. UV rays can cause wood to fade and degrade over time, but WPC fences are designed to resist such damage. In this test, composite fence boards are exposed to xenon lights simulating sunlight for 8 hours a day over two weeks. The results help determine how resistant the WPC fence is to color fading and material degradation due to UV exposure.

Why it matters:

A fence that loses its color or becomes brittle under the sun is not ideal for outdoor use. The UV test ensures that your WPC fence will stay vibrant and strong, even in regions with intense sun exposure.

3. Boiling Test: Resilience in Extreme Conditions

The boiling test is conducted to assess how WPC fence materials hold up under extreme heat and humidity. Samples are submerged in 95°C salty water for 8 hours per day, simulating tropical climates with intense heat and moisture. After 80 hours of testing, the material’s strength and durability are evaluated for signs of cracking, warping, or weakening.

Why it matters:

Whether you live in a humid area or near the coast, your WPC fence will be exposed to moisture and temperature fluctuations. The boiling test ensures that your composite fence board will maintain its durability in these extreme conditions.

4. Cooling Test: Performance in Freezing Temperatures

Just as WPC fences need to withstand heat, they must also perform well in freezing conditions. The cooling test subjects composite fence materials to -18°C temperatures for 8 hours per day over two weeks. This test simulates the effects of freezing weather, checking for brittleness, cracking, or other damage that could occur in cold climates.

Why it matters:

If you live in a colder region, your WPC fence should maintain its structural integrity during winter. The cooling test ensures that even in freezing temperatures, your modern composite fence will stay strong and functional.

FAQ About WPC Fences

Q: Do WPC fences require a lot of maintenance?

A: No, WPC fences are extremely low-maintenance. Unlike wood fences, they don’t require regular staining, painting, or sealing. A simple wash with soap and water is all that’s needed to keep them looking great.

Q: How do WPC fences perform in extreme weather?

A: WPC fences are designed to withstand a wide range of weather conditions, from intense heat and humidity to freezing cold. The tests mentioned above, such as the boiling and cooling tests, ensure that composite fence boards are built to last and perform well in extreme environments.

Make the Right Choice

When it comes to durability and performance, not all fences are created equal. With the WPC fence panel, you get the perfect blend of strength, low maintenance, and long-lasting beauty.

How to choose a composite fence supplier?

Trust MecoFence, a leading manufacturer of composite fencing, to provide you with a product that’s rigorously tested to withstand extreme conditions. Invest in a modern composite fence that’s built to last—because your outdoor space deserves nothing less than the best.

Contact: +86 180 2418 7532

Or Follow MecoFence on Facebook