In this guide, you’ll learn the critical differences between ASA, PVC, and WPC fencing and:

- The Chemistry of Durability (Why PVC Fails)

- The Style Factor of Fence Panel.

- Special Fence Feature: 100% Privacy with Ventilation.

- Installation & Logistics (The B2B Profit Maker).

- Repair & Maintenance (The “After-Sale” Reality).

- Structural Integrity (Wind & Impact).

- The Cost Analysis (Price vs. Value)

A topic that goes far beyond the standard composite vs. vinyl fence debate! Let’s dive in.

Every fence looks flawless on the day the installation crew drives away, but the real test of quality doesn’t happen until the first major storm hits or the third summer sun beats down.

For decades, fencing wholesalers and contractors have been forced to choose between two imperfect standards. You have standard PVC (Vinyl), which becomes brittle and yellows over time, or Wood Plastic Composite (WPC), which offers a premium look but kills your profit margins with its heavy shipping weight and difficult installation.

Durability Comparison: Why Standard PVC Fails vs. ASA

To understand why ASA is superior, we first need to be honest about why standard PVC often disappoints homeowners.

|  |

| PVC Fence Board | ASA Co-extrusion PVC Fence Board |

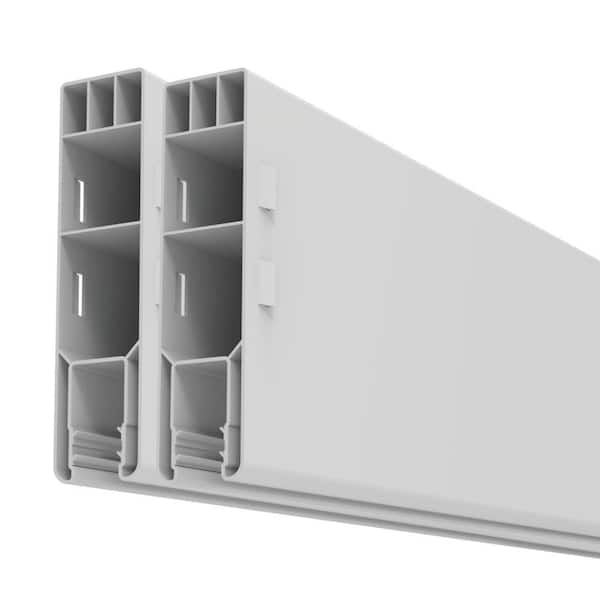

The “Mono-extrusion” Weakness Most standard vinyl fences sold at big-box retailers are “mono-extruded.” This means the board is made of the same basic plastic compound from the core to the surface. While this keeps manufacturing costs low, it leaves the plastic vulnerable.

The UV Attack When ultraviolet (UV) rays hit standard PVC, they attack the molecular bonds of the plastic. Over time—usually within 3 to 5 years—this causes the surface to degrade. You have likely seen this before: a white fence that looks chalky or has turned a sickly cream color.

The ASA Shield ASA (Acrylonitrile Styrene Acrylate) is different. It is not just plastic; it is an engineering polymer designed for extreme environments.

At Mecofence, we use Co-extrusion technology. Imagine the fence board has a core skeleton for strength, but it is wrapped in a “suit of armor” made of ASA. This ASA layer is chemically resistant to UV radiation. It doesn’t just reflect the sun; it ignores it.

This is why car manufacturers use ASA for side-view mirrors. They sit in the sun for 15 years and never turn white. We are bringing that same level of permanence to your backyard.

Aesthetics: ASA vs. WPC Fencing Texture

In the B2B world, we often focus on specs, but your end-customer is searching for the perfect fence to elevate their property value. This is where the matte finish of our ASA Co-extrusion PVC fence board creates a massive gap between itself and traditional Vinyl.

The “Plastic Look” Problem Standard PVC fences have a tell-tale shine. They look synthetic. For high-end residential projects or luxury villas, a shiny plastic fence cheapens the entire property. It screams “budget option.”

The Matte Finish & Wood Grain Our ASA Co-extrusion PVC fence board is engineered to mimic the sophistication of natural timber without the rot.

The ASA co-extrusion process allows us to apply a double-sided brushed texture. This eliminates the cheap plastic reflection. When you run your hand across an ASA board, it has a tactile, organic feel.

Color Depth that Lasts With WPC or wood, you often struggle with color consistency. With standard PVC, you are usually stuck with just White or Tan.

Because ASA is an acrylic-based material, it holds pigment incredibly well. We offer deep, rich colors like Teak, Rosewood, Antique, and Golden Oak.

According to our ISO 105-A02 testing (Grey Scale Rate 4), these colors don’t wash out. A homeowner can install a Rosewood ASA fence today, and it will retain that deep reddish-brown hue for decades, unlike wood which turns gray within two seasons.

Design: ASA FlowShield™ vs. Solid Vinyl Panels

Style is not just about color; it is about architecture, and our unique ASA Co-extrusion PVC Fence introduces a structural revolution with the FlowShield™ design.

The Privacy-Ventilation Paradox Homeowners want 100% privacy. They don’t want neighbors looking in. However, engineers know that a solid wall is a disaster for airflow. In humid climates, a solid wall creates a damp microclimate in the garden, promoting mold. In windy climates, a solid wall acts like a sail, catching the wind until the post snaps.

The Solution Our FlowShield™ system utilizes a unique board profile (129mm top / 80mm bottom). When stacked, they create a visual barrier that is completely opaque—you cannot see through it. However, the specialized gaps allow air to pass through freely. This “breathable” design reduces wind load significantly.

ASA vs. WPC Weight Comparison (The B2B Profit Maker)

If you are a wholesaler, your profit isn’t just the sale price; it’s the landed cost, which is why switching to lighter ASA Co-extrusion PVC fence boards is a financial game-changer.

The Weight Math WPC is heavy. A standard 6ft x 6ft Composite Fence panel is dense, often requiring two men to lift comfortably. ASA material is 50% lighter than WPC.

Let’s look at the logistics scenario:

Shipping WPC: You might fit 800 sets in a container. You hit the weight limit of the container before you fill the volume.

Shipping ASA: You can fit significantly more ASA sets in the same container because you hit the volume limit, not the weight limit.

Result: Your shipping cost per fence panel drops dramatically. In a global market with fluctuating sea freight rates, this efficiency is a massive competitive advantage.

| Cost Factor | Standard WPC Fence | ASA Co-extrusion Fence | The ASA Advantage |

| Material Cost | $$ (Medium) | $$$ (Premium) | ASA raw material is more expensive. |

| Weight per Panel | ~45 kg (Heavy) | ~22 kg (Light) | 50% Lighter. |

| Units per 40HQ | ~800 Sets | ~1,200+ Sets | +50% More Inventory. |

| Freight Cost per Unit | High ($12 – $15 avg) | Low ($7 – $9 avg) | Save ~40% on Sea Freight. |

| Final Landed Cost | High | Competitive | Freight savings offset material costs. |

Maintenance: Wood vs. PVC vs. ASA Fencing (The “After-Sale” Reality)

Every contractor hates the “callback,” and difficult winter fence maintenance is often the culprit. The modular nature of the ASA Co-extrusion PVC Fence solves this permanently.

The Nightmare of Repairing Wood & Vinyl With wood, if a board rots or warps, you have to pry it out, potentially damaging the rails. With standard PVC, in cold weather, it becomes brittle. If a lawnmower throws a rock at it, the entire panel can shatter.

The ASA Advantage: Modular Repair Because the FlowShield™ system is modular (individual boards stacked in an aluminum channel), repair is simple. You simply unscrew the top rail cap, slide out the damaged boards, and slide in a new board. Because ASA doesn’t fade, the spare boards you kept in the warehouse will still match the color of the fence installed 5 years ago.

Cleaning: The Hydrophobic Surface “Maintenance-Free” is a buzzword, but ASA backs it up. The surface is hydrophobic (repels water). This means dirt, bird droppings, and pollen don’t stick well to the surface. Rain usually washes the fence clean.

ASA Wind Resistance vs. Standard Vinyl

We briefly mentioned wind, but let’s look at the data proving why our ASA Co-extrusion PVC Fence passed Wind Resistance Level 9 testing.

The “Level 9” Standard Wind Resistance Level 9 equates to wind speeds of roughly 88 km/h. Most standard vinyl fences begin to wobble or warp at much lower speeds. The combination of the aluminum framework (which provides the skeletal rigidity) and the vented ASA boards (which reduce wind pressure) creates a system that can survive coastal storms.

Impact Resistance We also tested for impact. Using the ASTM D1037 standard, we verified that ASA absorbs energy rather than shattering. This is critical for fences near driveways, baseball fields, or areas with active children.

Cost Analysis: ASA vs. PVC vs. WPC Price Breakdown

Finally, let’s talk about the price difference between ASA, Composite Fencing, and standard Vinyl to understand the Total Cost of Ownership (TCO).

The Upfront Cost Yes, high-end ASA fencing costs more per linear foot than the cheapest, thinnest vinyl fence you can buy at a discount store. If your only metric is “cheapest price today,” ASA is not for you.

The Warranty Value However, B2B buyers know that TCO is what matters. We back our ASA products with a 15-year commercial warranty and a 20-year residential warranty. For a contractor, this warranty is a sales tool. You aren’t just selling a fence; you are selling peace of mind.

The Future is Here

The fencing market is shifting. Homeowners are becoming more educated; they know about “fading vinyl” and “rotting wood.” They are demanding better materials.

ASA Co-extrusion is the answer to that demand.

It is the rare product that aligns the interests of the entire supply chain: Wholesalers gain a massive logistics advantage with 50% lighter loads; Contractors get a faster, fatigue-free installation process; and Homeowners finally get a fence that stays beautiful for decades.

Ready to see the difference? Don’t just take our word for it. Contact our team to request a free sample kit. Feel the weight, scratch the surface, and test the locking mechanism. Upgrade your inventory to ASA today.

2026-02-02