Estimated reading time: 5 minutes

The modern fencing market is shifting toward composite fence systems — combining the natural texture of wood with the durability of advanced polymers.

Both Trex Seclusions and Mecofence offer durable, slat-style wood–plastic composite solutions. However, their installation methods, component structures, and field efficiencies differ in ways that wholesalers should understand.

This comparison aims to provide objective, data-based insights to help distributors, contractors, and developers choose systems that fit their business model, labor base, and logistics capacity.

Trex Seclusions: Engineered Precision for Traditional Framed Panels

Trex Seclusions is a framed composite fence system built for structural rigidity and precise alignment.

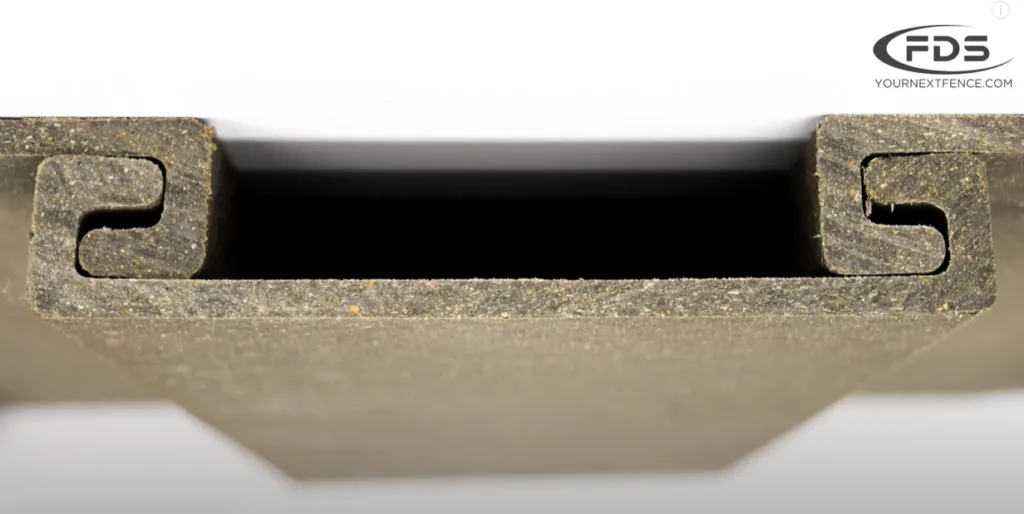

Each picket features an internal interlocking profile, as seen in the image below, forming a secure connection that reduces panel flex and maintains a uniform face.

Installation Summary

Set posts: 74½″ high, spaced 91″ on center.

Mark bracket positions: 5¾″ and 73⅝″ down from the top.

Attach brackets and assemble rails.

Insert and secure pickets, installing the final one from above.

Add post caps and finish with nails for tension.

This method produces a strong, uniform result, but it requires more measurements, cutting, and fasteners than newer slat systems.

Mecofence Slat Composite Fence: Simplified and Modular

Mecofence’s system focuses on ease, versatility, and secure interlock performance.

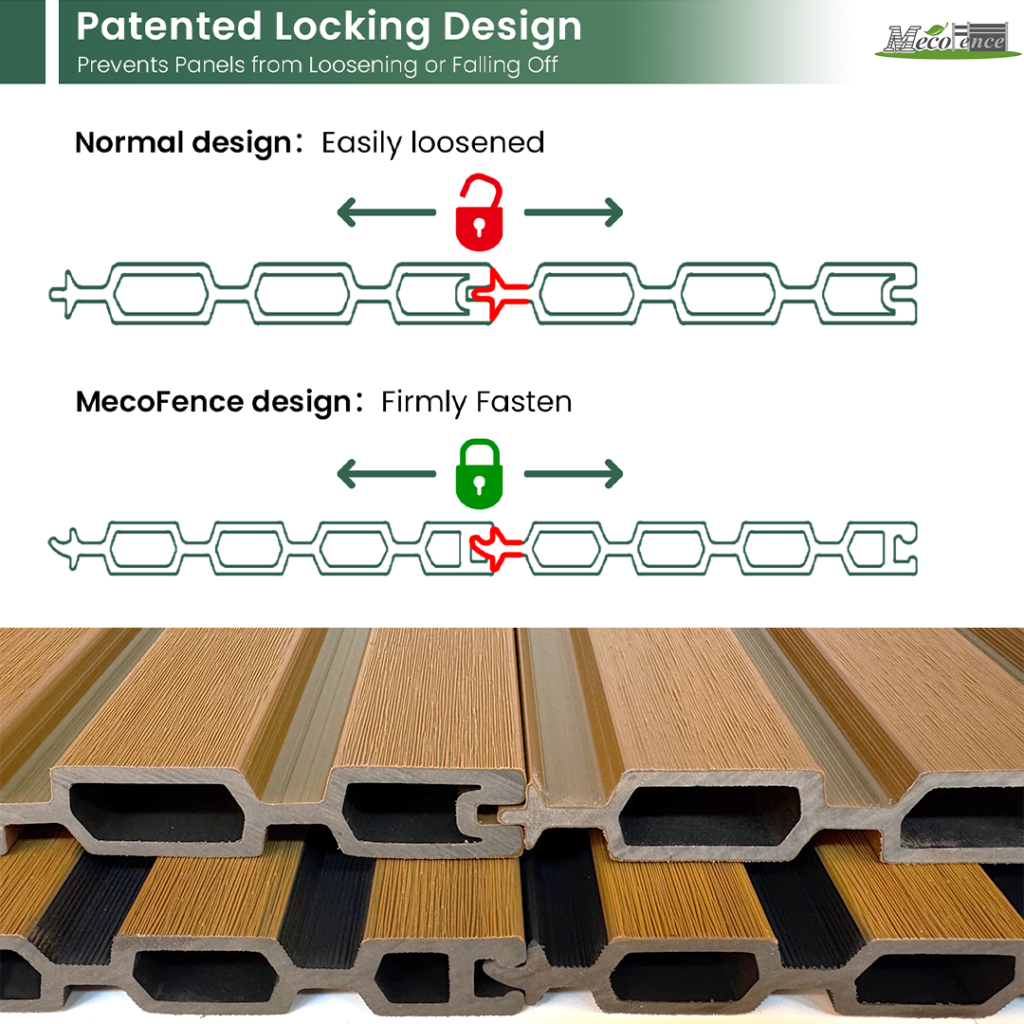

Its patented internal locking design, shown below, prevents slats from loosening or shifting once installed—a key advantage for long fence runs and temperature-variable environments.

Mecofence’s patented composite slat structure: locking profile prevents panels from loosening or detaching during expansion and contraction.

Installation Summary

Fix the post base and insert posts, checking plumb and level.

Attach the bottom rail between posts.

Insert interlocking slats by rotation, ensuring all face the same direction for uniform fit.

Lock the top rail and install post caps.

This four-step process minimizes fasteners, measuring, and alignment variables.

The result is a clean, modern slat appearance achieved with fewer tools and less training—an important factor for large-scale or multi-crew operations.

Technical Comparison

| Feature | Trex Seclusions | Mecofence Slat System |

|---|---|---|

| System Type | Framed picket-panel | Modular slat interlock |

| Core Material | Wood–plastic composite + aluminum reinforcement | Wood–plastic composite + steel base |

| Internal Core Design | Tongue-and-groove interlock | Patented S-lock mechanism |

| System Type | Framed picket-panel | Modular self-locking slat |

| Locking Method | Friction fit (groove and ridge) | Mechanical lock (positive engagement) |

| Color Options | Single-tone wood composite | Dual-tone finish options |

| Install Complexity | High (precise bracket layout) | Moderate (self-aligning boards) |

| Fasteners per Panel | Many (brackets, screws, nails) | Few (rails + limited screws) |

| Post Spacing | 91″ fixed center-to-center | 6ft fixed center-to-center |

| Field Cutting | Often required | Minimal |

| Aesthetic | Traditional privacy look | Contemporary slat design |

| Training Time | Moderate to high | Low to moderate |

| SKU Range | Multiple parts (posts, rails, brackets, caps) | Simplified (posts, rails, slats, caps) |

Wholesaler-Focused Considerations: Orientation, Finish, and Efficiency

For wholesalers, the ease of installation and adaptability of design directly influence both sales potential and supply chain simplicity.

1. Dual-Tone Appeal for Broader Market Fit

Mecofence’s dual-tone board design offers visual variation on both sides of the fence—ideal for residential projects where neighbor-facing aesthetics matter.

This allows wholesalers to promote one SKU line to multiple design profiles, simplifying inventory while appealing to both modern and traditional buyers.

2. Vertical or Horizontal Layout Options

Unlike single-orientation systems, Mecofence’s fence boards are engineered to install either vertically or horizontally, giving architects and installers greater creative flexibility without requiring new components.

For wholesalers, this versatility means fewer SKUs, broader project compatibility, and easier upselling into different style markets.

3. Simplified Installation = Scalable Business

Crews can complete Mecofence panels faster, with less layout correction, reducing training overhead and jobsite variability.

That consistency translates directly into predictable labor hours, fewer callbacks, and more reliable customer satisfaction—critical advantages for growing wholesale programs.

Balanced Engineering for Different Fence Markets

Both Trex Seclusions and Mecofence stand as durable, sustainable composite fencing systems backed by proven engineering.

Trex remains a solid choice for customers valuing traditional framed structure and brand familiarity.

Mecofence, meanwhile, introduces a modern, installer-friendly system with dual-tone finishes and multi-orientation options—simplifying both installation and inventory management.

For fence wholesalers, the key takeaway is choice alignment:

Trex suits projects prioritizing classical design and precision structure.

Mecofence suits operations emphasizing speed, flexibility, and scalable logistics.

Both systems reflect how far composite fence installation has advanced—combining the aesthetics of wood with the practicality and longevity of engineered materials.